Vaccum Temperature and Climatic Chamber

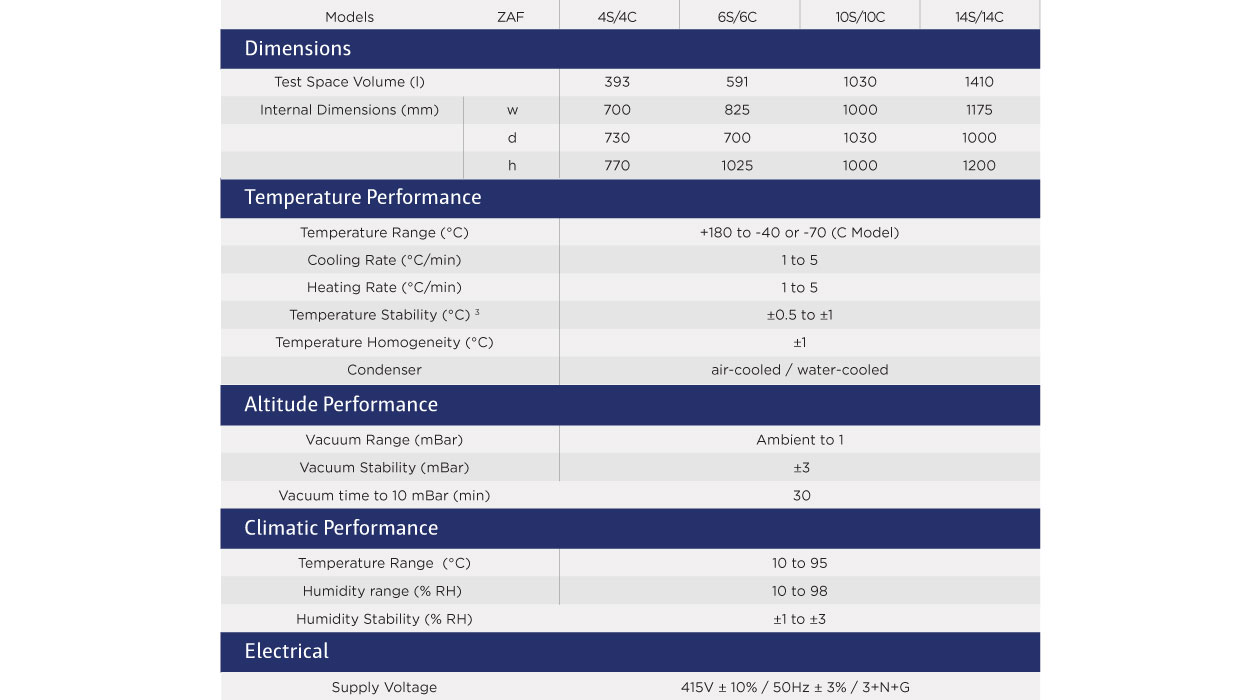

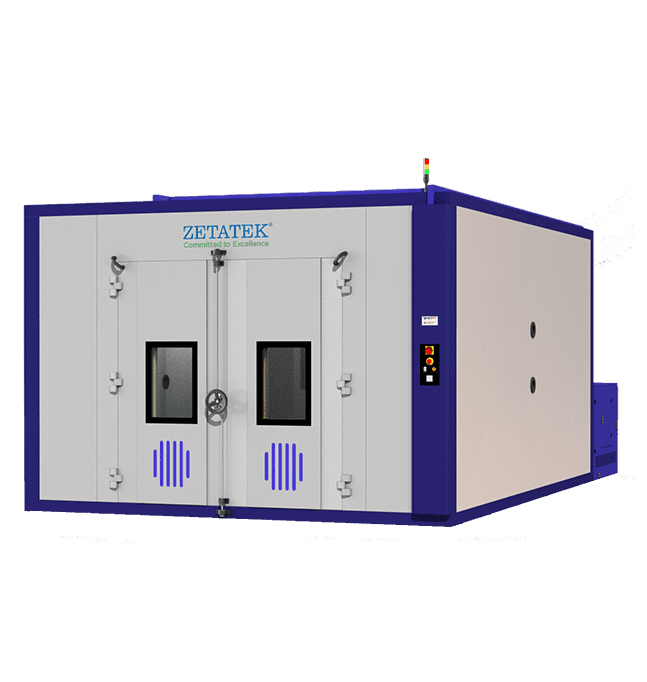

Vacuum Temperature and Climatic chambers from Zetatek are a revolution in environmental testing. Simulating a wide range of environmental conditions from the equator to the poles and from the sea level to stratosphere, these chambers stand out for their brilliant design, exceptional build quality, performance and reliability. Combining over three decades of experience in the design and manufacture of environmental test chambers, Zetatek, the market leader in the industry, offers test chambers of sizes varying from 400 litres to 1400 litres. They have a vacuum range from ambient to 1 milli bar, temperature range from -70°C to +180°C and humidity from 10% RH to 98% RH.

These chambers can be used anywhere from research and development to production purposes or even for quality testing. From circuit boards to satellites and missiles, from mechanical components to cars, any specimen can be subject and qualified to various environmental condition. Our chambers find their paramount application in industries such as defence, aerospace, automotive and electronics.

Features

Exterior

The outer panels are powder coated for corrosion-resistance and aesthetic appeal.Interior

The test space is made from Stainless Steel 304 which provides excellent resistance to corrosion. A mirror finish is provided to elevate the aesthetic look. The inner tank is welded airtight so that moisture does not leak into the insulation.Insulation

Multilayer Composite insulation with rock wool and phenolic foam is used to provide resistance against high and low temperature with only 100mm insulation thickness.Uniform Air Flow

Specially designed bottom false sheet with baffles is used to uniformly distribute the air throughout the test space providing uniformity/homogeneity within ± 1 °C.Ports Hole

Access port is provided for connecting cables to the test specimen inside the test space during testing. Ports Holes are covered with soft silicon sealing ports to avoid thermal leakages.Heavy Duty Vacuum Pumps

The test space is evacuated with the help of heavy duty vacuum pumps for excellent performance and reliability.Klima Controller

Connectivity

- Connectable to chamber through Ethernet or Wi-Fi

- Accessible from anywhere over the internet

- Remote troubleshooting for immediate and efficient service and maintenance.

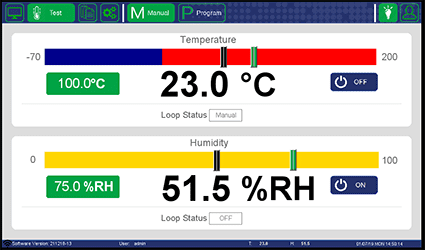

Touch Screen

- Multiple touchscreen options: 7”, 10” and 15”

- 800 X 480 or 1024 x 600 resolution colour displays

- TFT widescreen display with 16.7M colours

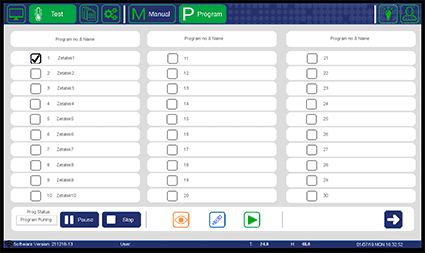

Programs

- Capability to create upto 99 programs

- Each program can have upto 999 cycles which ultimately results in unlimited segments

- Numerical entry of profile parameter

- Delayed or scheduled start of programs

Data Logging

- Recording of unlimited test data

- Transfer of test data through a USB pen drive

- Exportable to CSV file for easy analysis and graphing in Excel.

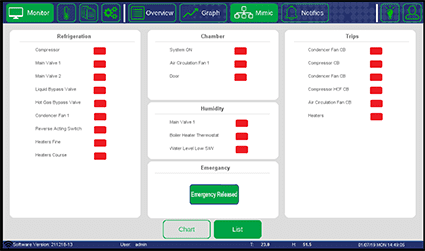

Safety, Notification and Alarms

- Automatic and periodic system maintenance notifications.

- Cut-off for High and Low temperatures

- System malfunction alarms such as door open, compressor trip, heater trip, fan motor trip, etc

- Alarm log feature for troubleshooting

Software

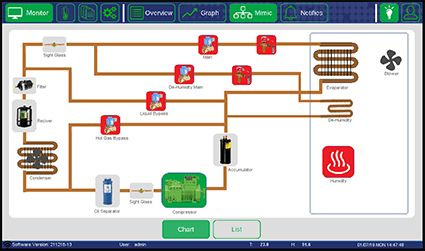

- Numerical and graphical visualization of test parameters

- Synoptic chart for status monitoring

- Program and manual mode of chamber operation

- Report generation for analysis and evaluation

- Zoom in, zoom out and scroll of graphs.

- Standard Pre-Loaded Profiles (Example: MIL STD 810)

- Multizone PID for effective control.

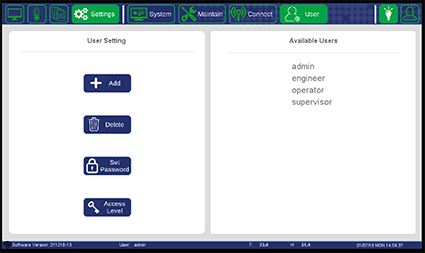

Secure Access

- Safe access through personalised passcode.

- Multiple user levels User: Access to run tests and change set points

Supervisor: Access to change settings and system parameters

Admin: Access to service modules

Multi-Platform Support

- Klima Controller can be fully operated from multiple platforms such as a smartphone, tablet or a PC.

Options

- Multi-level adjustable wire shelves.

- Water cooled system available for better performance

- Test specimen temperature measurement/control

- Multiple Independent sensors for temperature measurement

- Fresh air or dry nitrogen purging

- Water softener

- Reinforced Floor for heavy specimens

- External Electrical terminals

- Multiple portholes with 75mm or 125 mm diameter.

- Ultra-Low temperature cooling with Liquid Nitrogen

- External Refrigeration pack.

- Test space made from SS 316

- External panels made from Stainless Steel