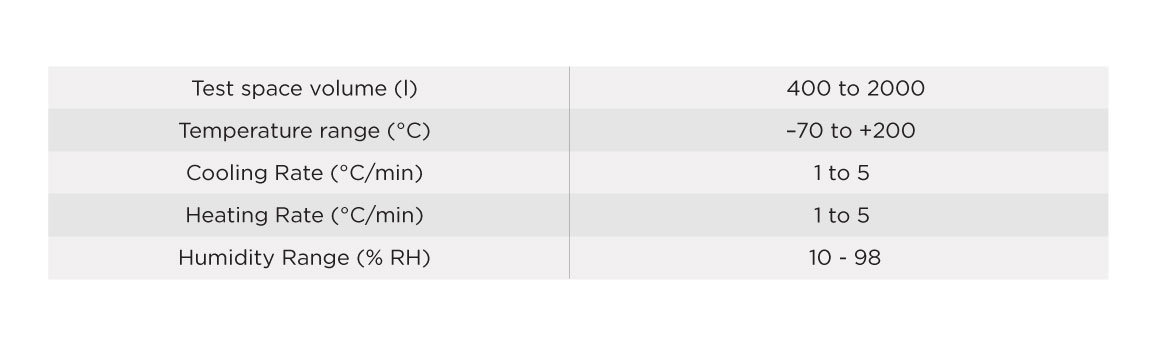

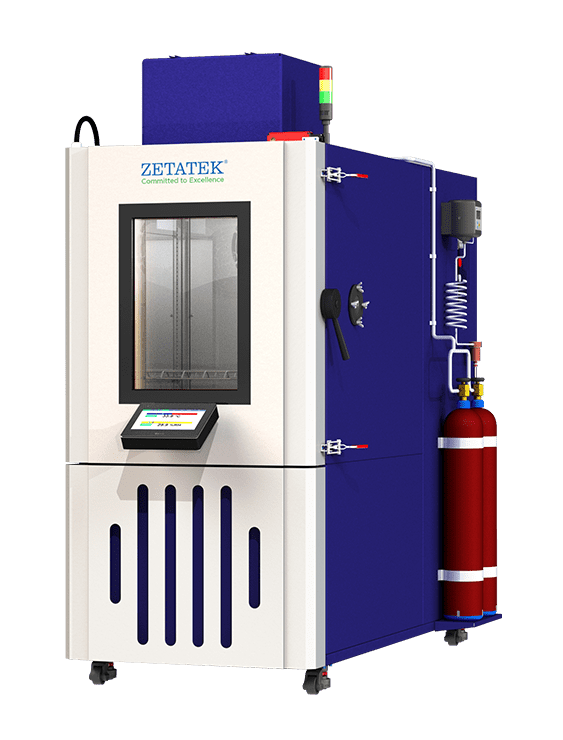

Battery Testing Chamber

Battery testing mainly involves the analysis during fast charging and discharging under simulated real world conditions or under extreme stress. These tests can be very dangerous and can cause the release of poisonous/explosive gases, spontaneous fires or even explosions.

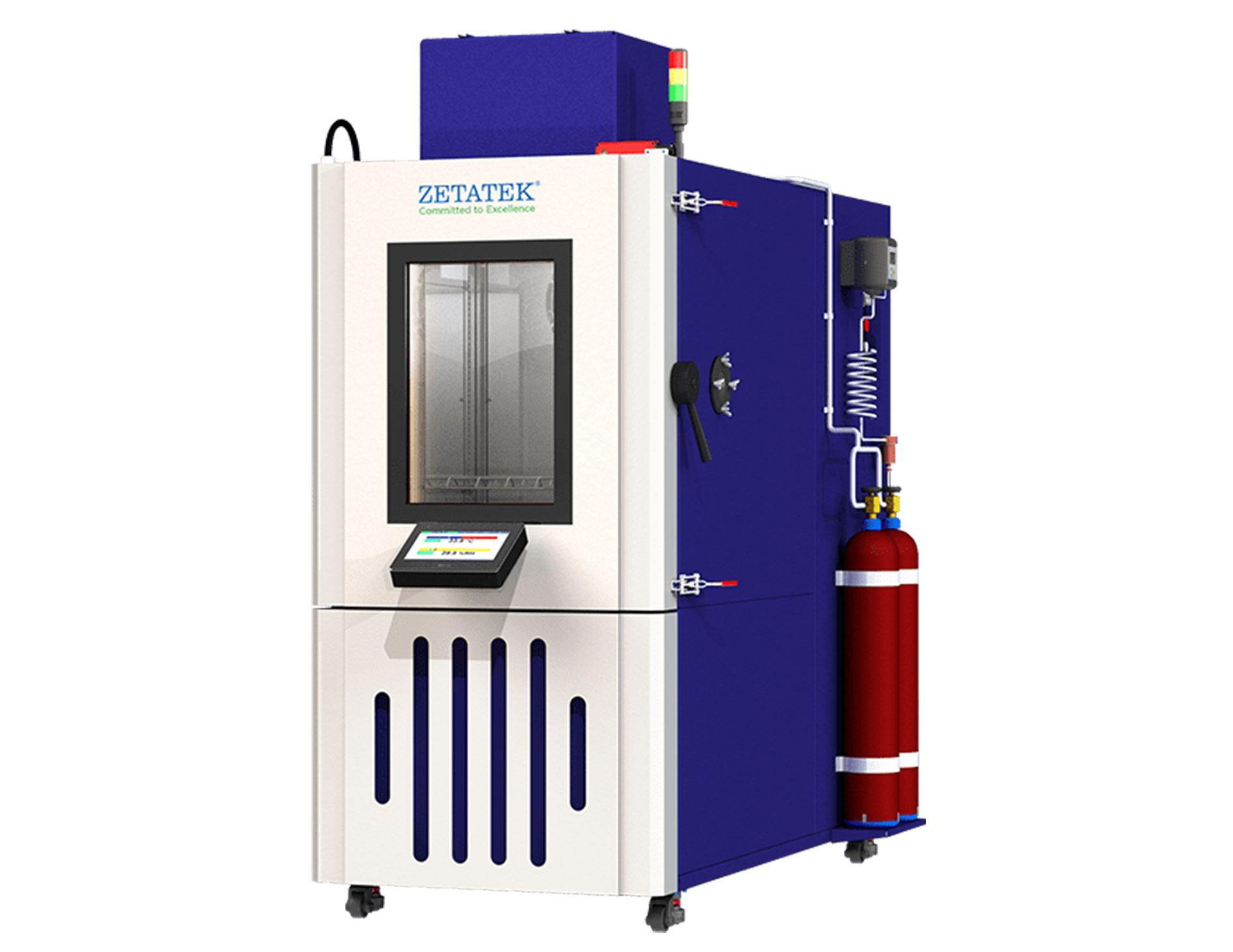

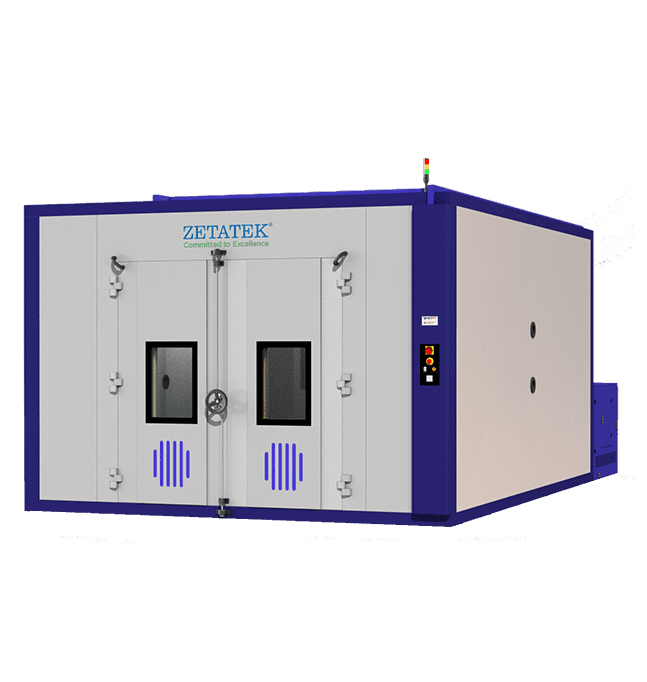

Zetatek is proud to introduce its new range of Battery Testing Chambers which are equipped with a host of safety features which enable the users to perform various test with assured safety in the laboratory.

Safety Features

Electronic Door Lock

Chamber door is locked using an Electro-Magnetic door lock. During testing, the chamber may contain hazardous gases released from the batteries and the lock prevents users from accidentally opening the door.Status Indicator and Alarm

A visual status indicator can be used to monitor the chamber’s status from a distance. A red lamp flashes during any faults in the system along with an audible sound which can quickly alert operators.Retaining Clamp for Port Hole Plugs

Due to pressure differential that may arise between the chamber test space and the ambient atmosphere during testing, the port hole plugs are secured using a retaining clamp.Temperature Limited Heaters

Heater surface temperatures are maintained below the auto ignition temperature of the combustible gases that may be released from the batteries, thereby preventing ignition.Mechanical Door Latches

Chamber Door is secured with sturdy mechanical latches on both sides. Any increase in pressure inside the chamber is safely contained.Gas Monitoring

Concentration levels of Carbon Monoxide (CO) and Hydrogen (H2) are monitored using a sampling system with electrochemical sensors.Fire Detection and Alarm System

Fire detection is possible by monitoring the carbon monoxide levels or by a sudden increase in chamber temperature. Once fire is detected, an audio-visual alarm can be triggered for alerting the operator.Fire Suppression/ Extinguishing

When a fire is detected inside the test space, it is extinguished by flooding the test space with carbon dioxide (CO2) or Nitrogen (N2).Chamber Inertisation

After the completion of a test, the chamber may be intertised with nitrogen (N2) in order to flush out any hazardous or combustible gases and reduce the oxygen concentration before opening the door.Oxygen Measurement

Oxygen measurement is used in conjunction with the chamber inertisation to monitor the concentrating levels and control the nitrogen flushing.Pressure Relief Vent

A pressure relief vent is provided to equalize the pressure in the chamber during inertisation or flushing of CO2.Burst disk

In the case of an explosion, there is a sudden release of gas and increase of pressure inside the chamber. A Burst disk is provided to release this pressure into an exhaust duct.Klima Controller

Connectivity

- Connectable to chamber through Ethernet or Wi-Fi

- Accessible from anywhere over the internet

- Remote troubleshooting for immediate and efficient service and maintenance.

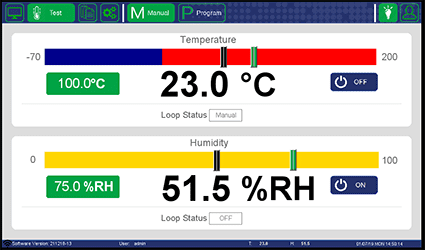

Touch Screen

- Multiple touchscreen options: 7”, 10” and 15”

- 800 X 480 or 1024 x 600 resolution colour displays

- TFT widescreen display with 16.7M colours

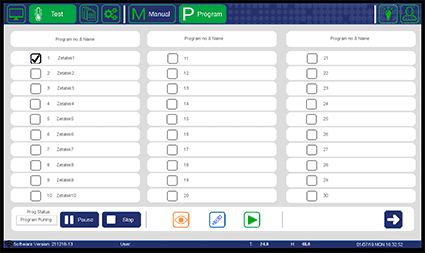

Programs

- Capability to create upto 99 programs

- Each program can have upto 999 cycles which ultimately results in unlimited segments

- Numerical entry of profile parameter

- Delayed or scheduled start of programs

Data Logging

- Recording of unlimited test data

- Transfer of test data through a USB pen drive

- Exportable to CSV file for easy analysis and graphing in Excel.

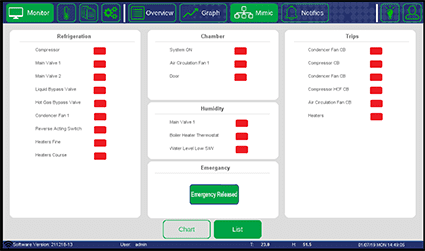

Safety, Notification and Alarms

- Automatic and periodic system maintenance notifications.

- Cut-off for High and Low temperatures

- System malfunction alarms such as door open, compressor trip, heater trip, fan motor trip, etc

- Alarm log feature for troubleshooting

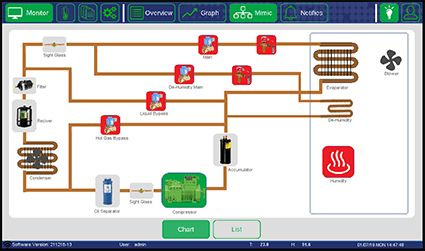

Software

- Numerical and graphical visualization of test parameters

- Synoptic chart for status monitoring

- Program and manual mode of chamber operation

- Report generation for analysis and evaluation

- Zoom in, zoom out and scroll of graphs.

- Standard Pre-Loaded Profiles (Example: MIL STD 810)

- Multizone PID for effective control.

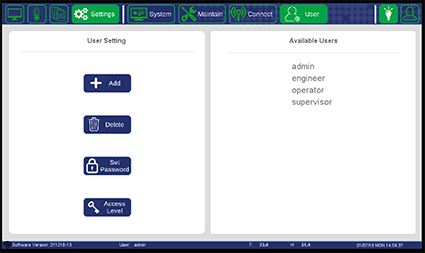

Secure Access

- Safe access through personalised passcode.

- Multiple user levels User: Access to run tests and change set points

Supervisor: Access to change settings and system parameters

Admin: Access to service modules

Multi-Platform Support

- Klima Controller can be fully operated from multiple platforms such as a smartphone, tablet or a PC.

Options

- Multi-level adjustable wire shelves.

- Water cooled system available for better performance

- Test specimen temperature measurement/control

- Multiple Independent sensors for temperature measurement

- Fresh air or dry nitrogen purging

- Water softener

- Reinforced Floor for heavy specimens

- External Electrical terminals

- Multiple portholes with 75mm or 125 mm diameter.

- Ultra-Low temperature cooling with Liquid Nitrogen

- External Refrigeration pack.

- Test space made from SS 316

- External panels made from Stainless Steel